Background:

- Damage in practice to forged steel wheelsets can be attributed to cyclic fatigue.

- Although wheelset shafts are designed for failure-free operation over the entire service life, damage can occur during operation, which is caused, for example, by a mechanical-corrosive complex stress.

- Therefore, the waves are checked by inspections and repaired if necessary.

- Applied internal compressive stresses in the area of the surface of the shaft contribute to increasing the fatigue strength and in particular the corrosion fatigue strength.

- However, thermal processes, such as induction hardening, have not yet been adequately evaluated for their effect.

FOSTA research project (P 1189):

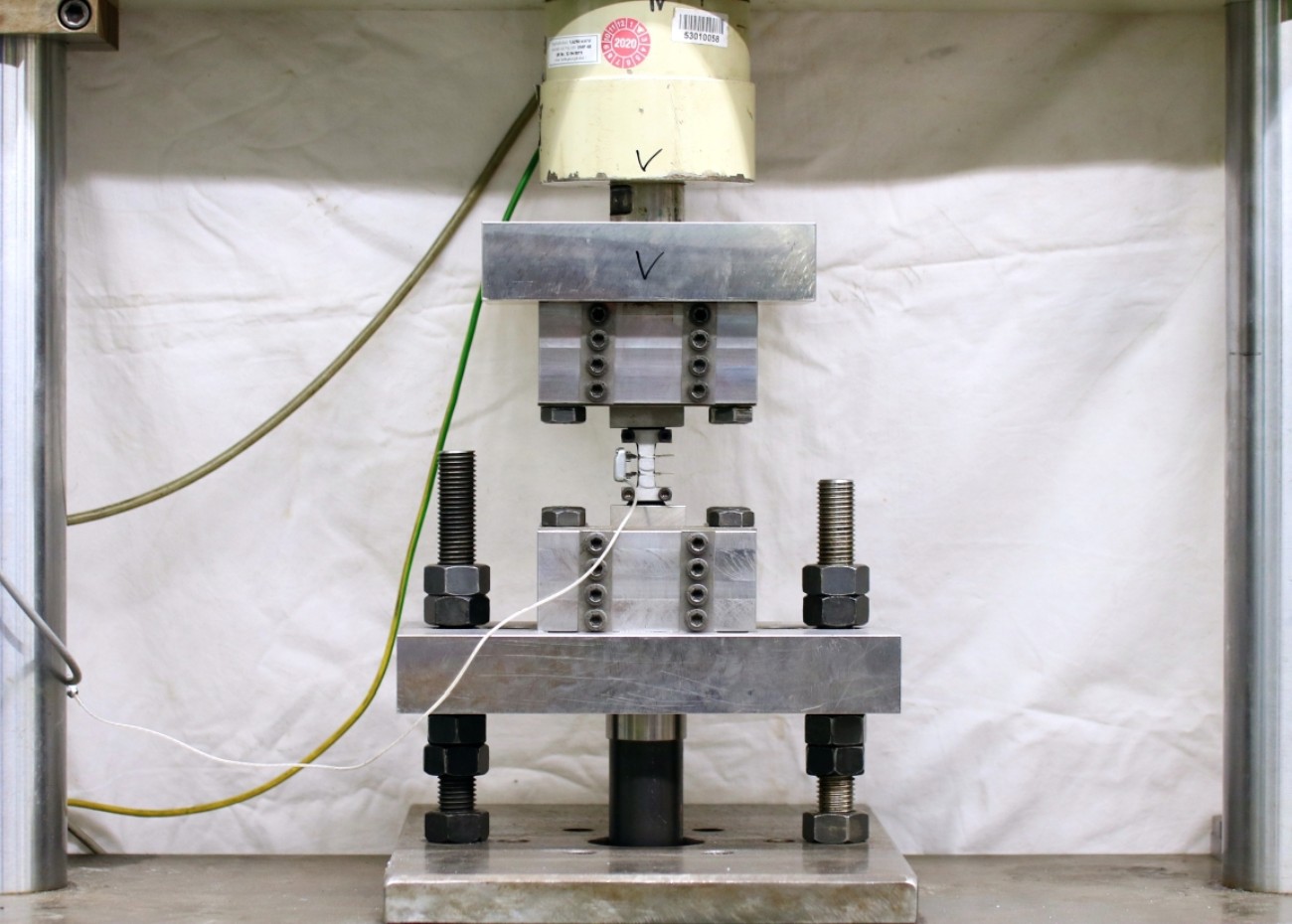

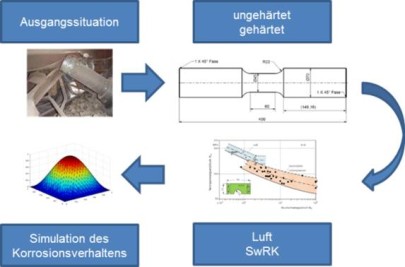

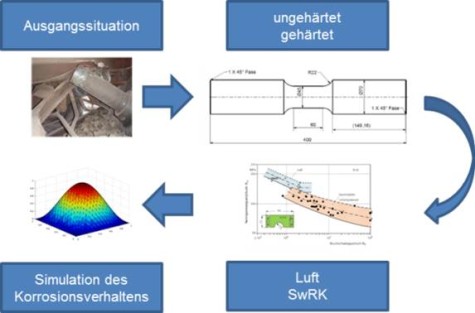

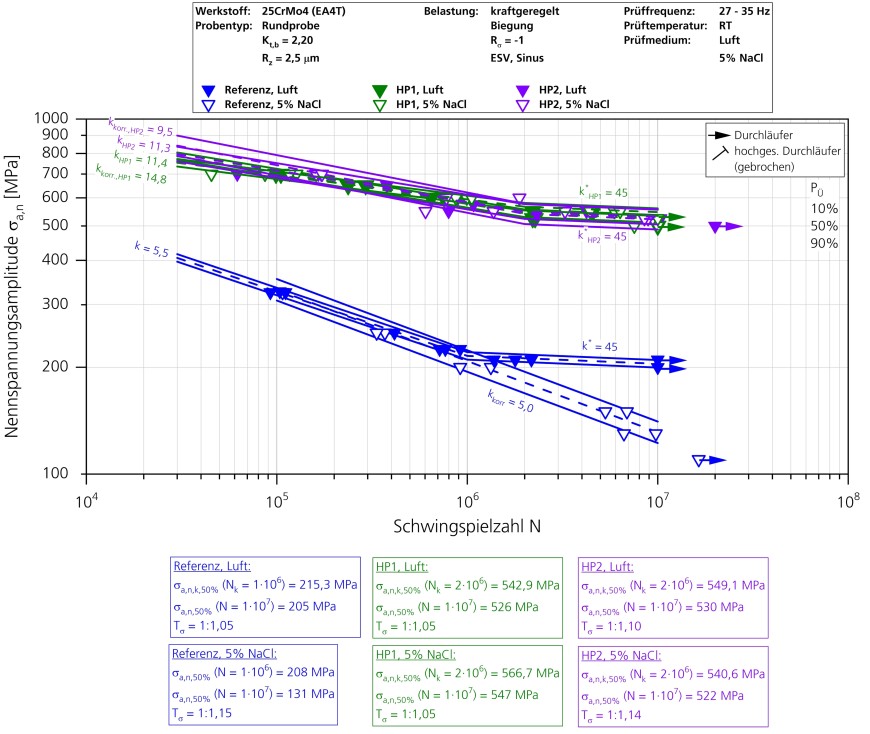

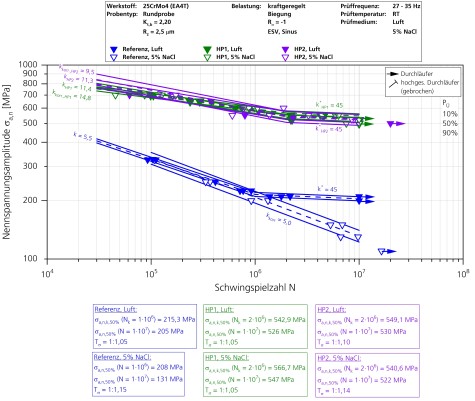

- Investigation of the corrosion fatigue strength of hardened and uncured EA4T (25CrMo4) samples with and without pre-damage under constant and variable amplitudes.

- Adjustment of the hardness parameters depending on the results on corrosion behavior and durability.

- Investigation of field-relevant damage due to corrosion.

- Development of a model for the numerical simulation of corrosion behavior.

Description:

In addition to purely mechanical stress, wheelset shafts are frequently subject to a simultaneous cyclic, mechanical-electrochemical complex stress (vibration cracking corrosion) due to weather conditions. In particular, the vibration crack corrosion is associated with metallic materials, even with stainless steel grades, with a fatigue strength drop of more than 50%. For the improvement of the vibration resistance properties, technological processes for surface hardening are particularly effective, but not currently integrated in the production process of wheelset shafts. The effectiveness of mechanically introduced residual compressive stresses by deep rolling or blasting, also to increase the corrosion fatigue strength, are already known. On the other hand, thermo-chemical (e.g., nitriding) or thermal processes (e.g., induction hardening) are not yet sufficiently qualified in their ability to increase the fatigue strength of steels in corrosive environments.

Within the framework of the project, the surface treatment process 'induction hardening' to increase the corrosion fatigue strength of wheelset axles made of the material EA4T (25CrMo4), which has proven itself in passenger and high-speed train traffic as well as suburban trains, subways and trams, will be examined and verified. because it has clear advantages over other processes (effective depth, hardness, ductility). In the future, this should completely avoid the rare but sometimes high costs and fatal consequences of breaking axles of wheelset axles. Perspectively, the waiver of corrosion protection, the increase in the fatigue strength in fretting corrosion (interference fit of the wheel disc on the axle), use of a cheaper material with sufficient fatigue strength and a reduced inspection effort can be expected.

Contact: