A strong tonal noise excitation occurs when meshing conventional spur gears through the strictly regular arrangement of the teeth. This noise is referred to as gear whine. Gear whine is perceived as an unpleasant noise, which often leads to customer complaints and negatively influences the product’s quality.

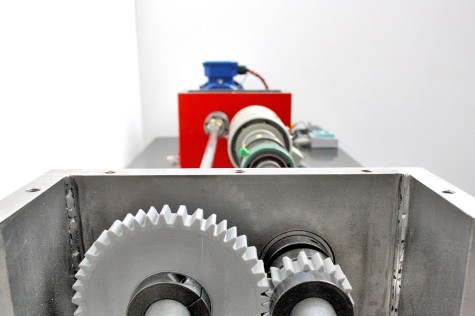

In order to prevent gear whine in gear trains, an innovative approach is investigated by the research group System Reliability, Adaptive Structures, and Machine Acoustics SAM of the Technische Universität Darmstadt. The principle of strictly regular (equidistant) pitch of the teeth along the circumference of spur gears is replaced. Through an optimized variation of individual tooth positioning and tooth thicknesses, an irregular gearing is developed – the inequidistant gearing.

Sound example: conventional equidistant gearing (measured at 1500 rpm)

Sound example: innovative inequidistant gearing (measured at 1500 rpm))

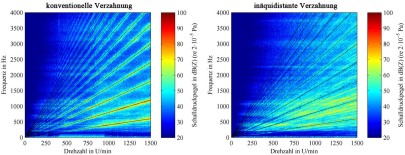

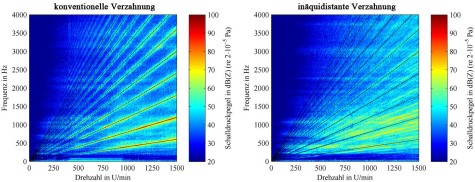

- Reduced annoyance of the meshing noise – Through the irregular arrangement of the teeth, the periodicity of the tonal noise excitation is reduced. The meshing orders no longer stand out dominantly, rather are lost in the newly emerging sidebands. The annoying tonal noise character is shifted towards a more pleasant, white noise-like character. Furthermore, the sound character is moved to lower frequencies, which also leads to a reduction in annoyance.

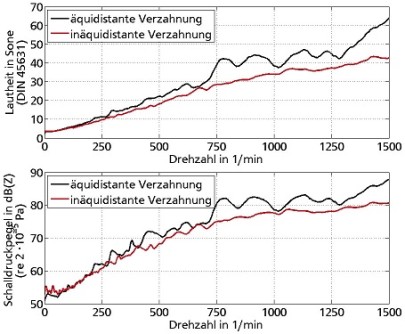

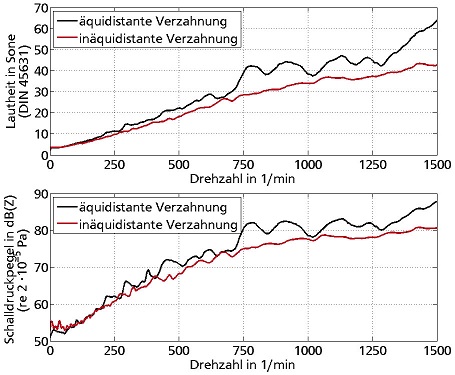

- Reduced loudness and reduced total sound pressure level – In the illustration to the side, the experimentally investigated results for the loudness and the sound pressure level (SPL) at increasing rotational speeds are depicted. Significantly lower values over the entire rotational speed range are achieved for the loudness (top diagram) with inequidistant toothing (red line). The noise is perceived subjectively less loud by humans and thus is felt to be less annoying. The tendency that the inequidistant gearing is quieter can also be seen for the sound pressure level (SPL, bottom diagram). Thus, the inequidistant gearing also leads objectively to less noise.

- Reduced excitation of structural resonances – The dominant orders of the meshing frequency are less excited. Instead, a broad mixture of frequencies, each with smaller amplitude, is excited. As a result, the resonances of adjacent structures (e.g. gearbox housing) are less excited, which in turn leads to reduced sound radiation.

Contact